Professional Highlights

Senior Design Project: Compliant Flap

For Work

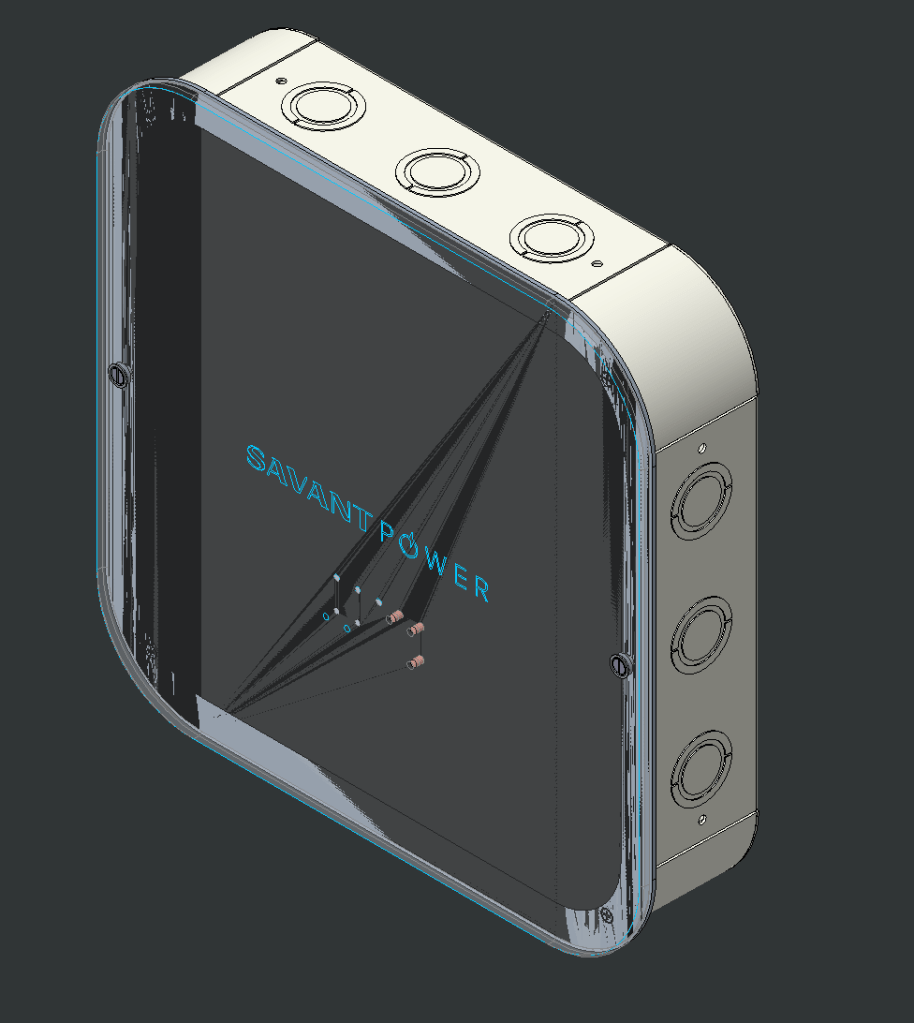

Enclosure Design

My longest project at Savant was to assist in the 3D CAD and BOM changes to one of their flagship electrical product lines. I had to make this 3D model fit for rapid design parameter changes through parametric modeling to allow for easy 3D updates. While the 3D was my primary responsibility for this project, I would also assist with it’s documentation, part sourcing, and it’s product art.

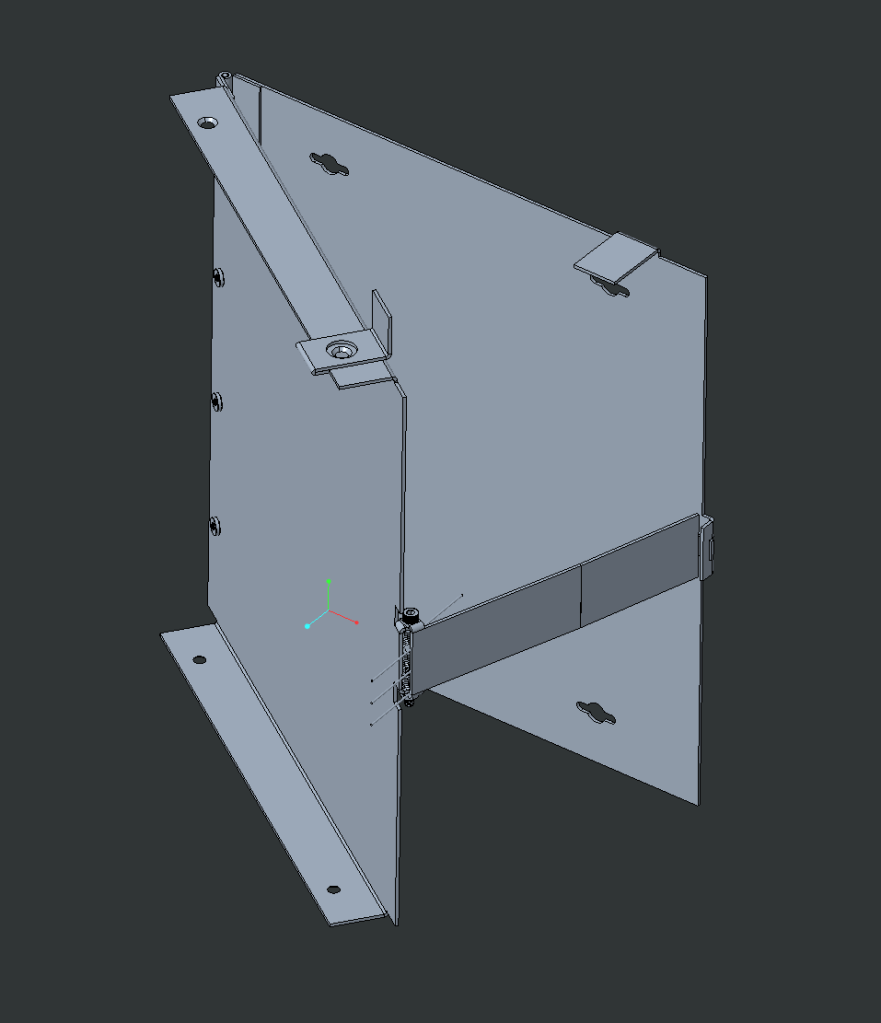

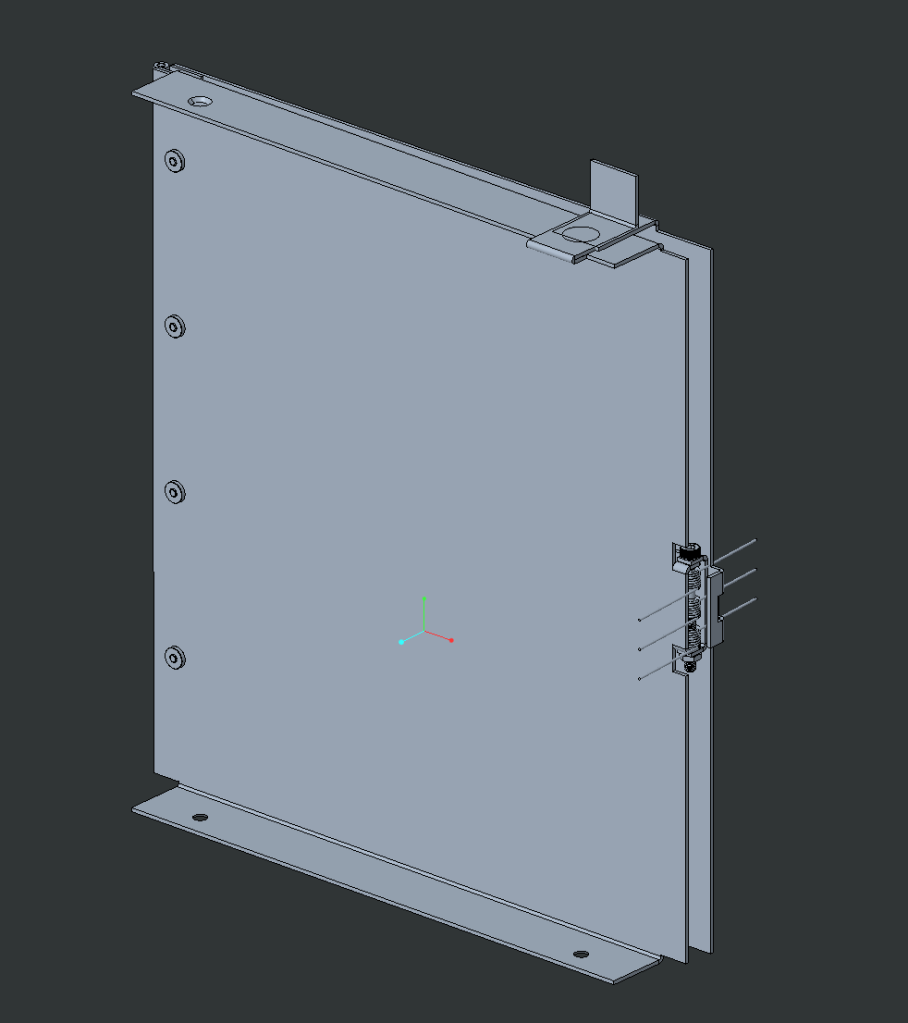

Electrical Equipment Hinge

An independent project given to me at Savant was to design a product mount with a hinge and kickstand. This hinge was to open up to a specified angle so electricians could easily access the side of the product. Other design constraints included the use of sheet metal, off-the-shelf parts for ease of prototyping, and a locking mechanism to secure the product in it’s retracted position.

Outline Restriction Drawings

At Savant, I was often tasked with one-off projects, such as Outline Restriction Drawings. These drawings were developed by the mechanical department to give the electrical department an idea of how to layout their PCBAs. They outline keep-out zones, through-holes for component solder points, and height restrictions for low-space areas of the assembly.

Keypad Improvements

A more R&D-type project I had at Savant was the analysis and improvement of a backlit keypad device. I was tasked with finding a solution to the uneven lighting present in the text of individual keys. Attached here is a power-point presentation I made summarizing my testing.

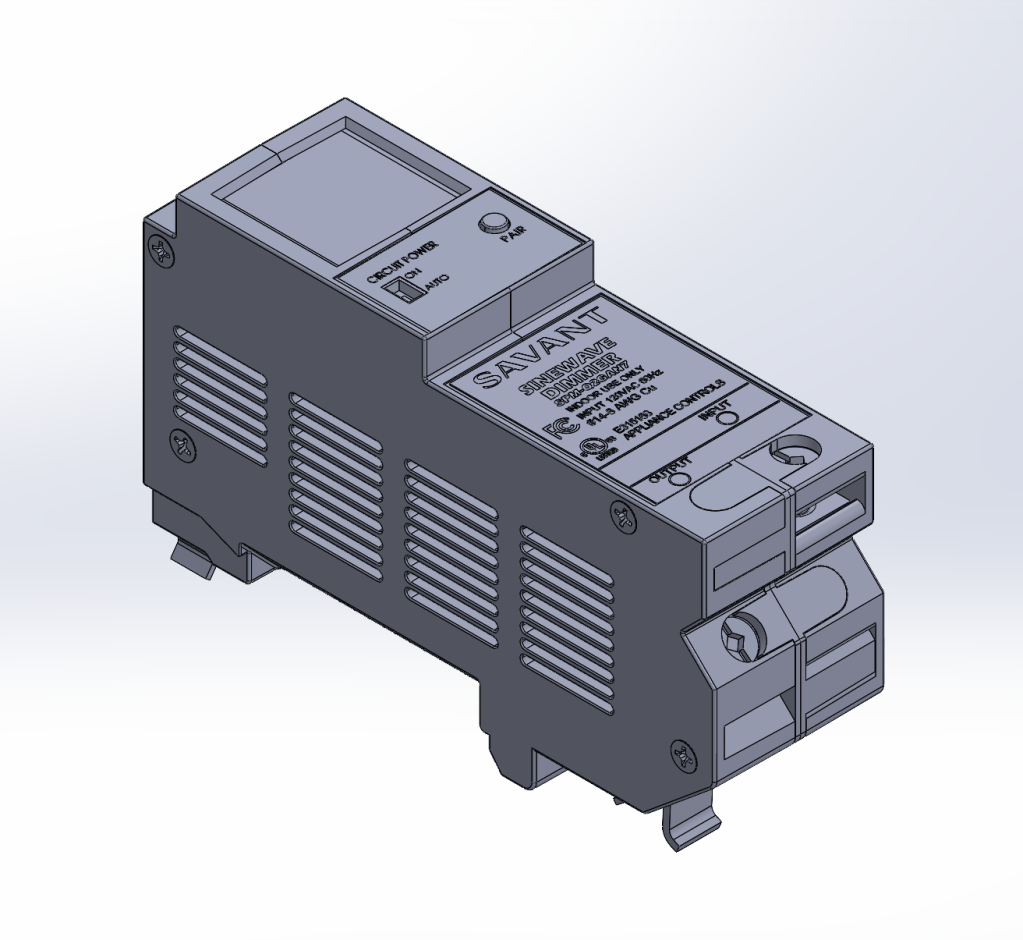

Breaker Companion Redesign

As a bi-lingual CAD user (fluent in Solidworks and Creo ProE) I was given projects that used multiple software. One such project involved the modification of an existing companion-breaker’s profile to fit in a new load-center. This project tested my ability to switch between Solidworks and ProE to redesing an enclosure while also maintaining consistent CAD practices.

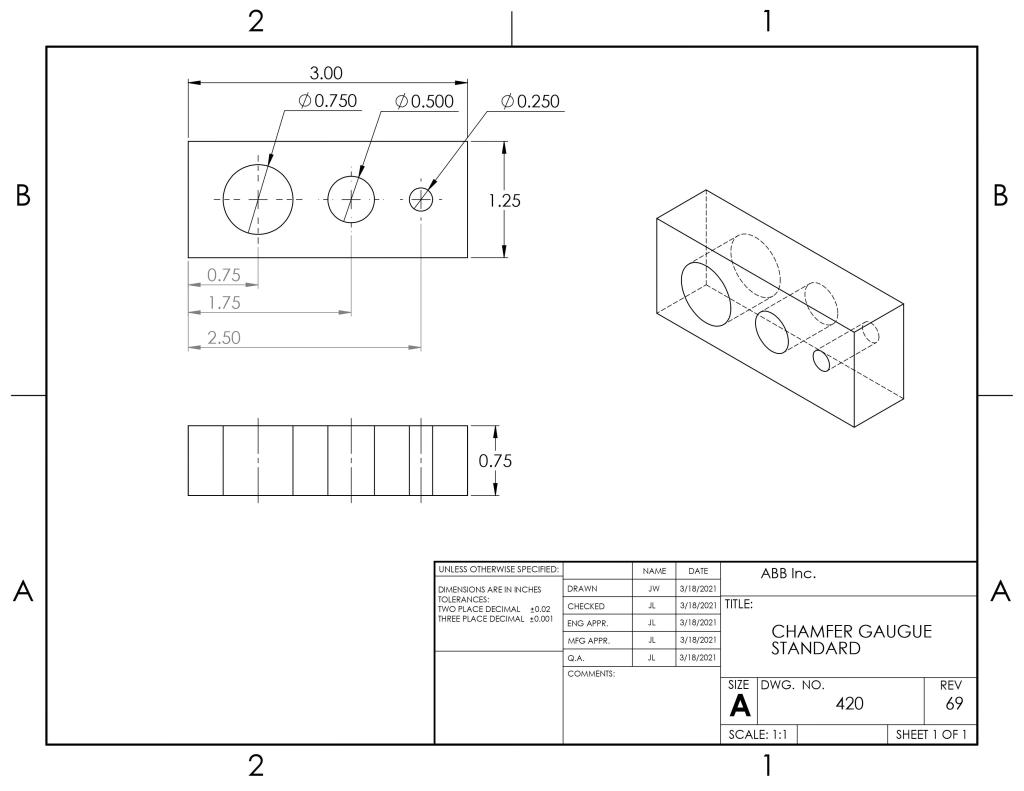

Chamfer Gauge Standard

The first part I designed professionally. This standard was used to calibrate different-sized chamfer gauges at ABB Auburn. The parts were cut with wire EDM machines to maintain the necessary tolerance of one-thousandth of an inch and made of pre-hardened steel to keep from waring. When the holes eventually lose calibration, the part can be faced several times to remake the edge required for chamfer gauging.

Plug Gauge

Plug gauges are devices that hold go-nogo pins to test the minor diameter of a threaded hole. I was tasked with designing a handle out of in-house stock to be repurposed as a Plug Gauge. My solution consists of two 4.5 inch pieces of I-Beam stock, each with a 1/4-20 clearance hole and a 1/4-20 tapped hole that are used to clamp down on the two pins. Each clearance hole is to be placed adjacent to the other half’s tapped hole and fastened with a bolt. A key feature of this part is it’s symmetry; the assembly is made from one part, so only that part has to be manufactured. This solution works with thousands of sizes of pins and was incredibly cheap to produce because the stock was readily available, required little modification, and little manufacturing time.

Discipline Tracking Sheet

My Excel magnum opus at ABB. Seeing my excel skills from previous works, the HR department asked me to make a spreadsheet that kept track of employees’ disciplinary status based on the company’s write-up policies. The spreadsheet had to have several access levels, backup and autosave features, automatic level calculations, and more. Here is a copy of my solution. It has some features like auto-closing disabled and for the sake of confidentiality, I changed the names to be randomly generated. When you download it, you will have to open it once to enable editing and then open it again to access it’s features. To log in as any user (except “Jacob Willette”), use their first name in all lowercase as their password. Different users have different access levels and can change and store information to varying degrees. Also available is the manual so you can read about the functions this sheet has to offer. Feel free to try and break this document and please let me know if you do!

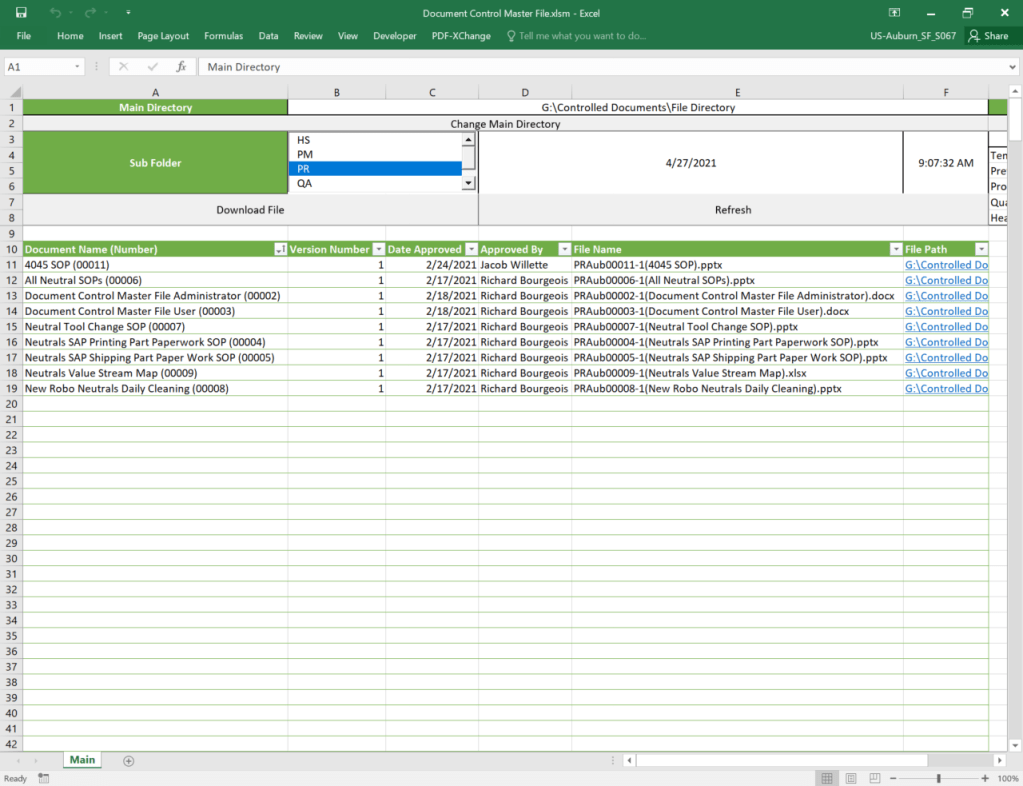

Document Control System

A goal of ABB Auburn is to become ISO-9001 certified and this requires some form of document control. My document control system presents users with the most up to date approved files available to them. The purpose is to make it impossible for individuals to use incorrect documents when doing their work and make sure documents are centralized. Admins are able to create, revise, approve, and import files into this system based on templates. All files have the same strict naming convention as outlined in the manual. I am not able to provide a copy of this file because it is heavily tailored to ABB’s servers in Auburn, but the attached manuals should provide a good idea about it’s functionality.

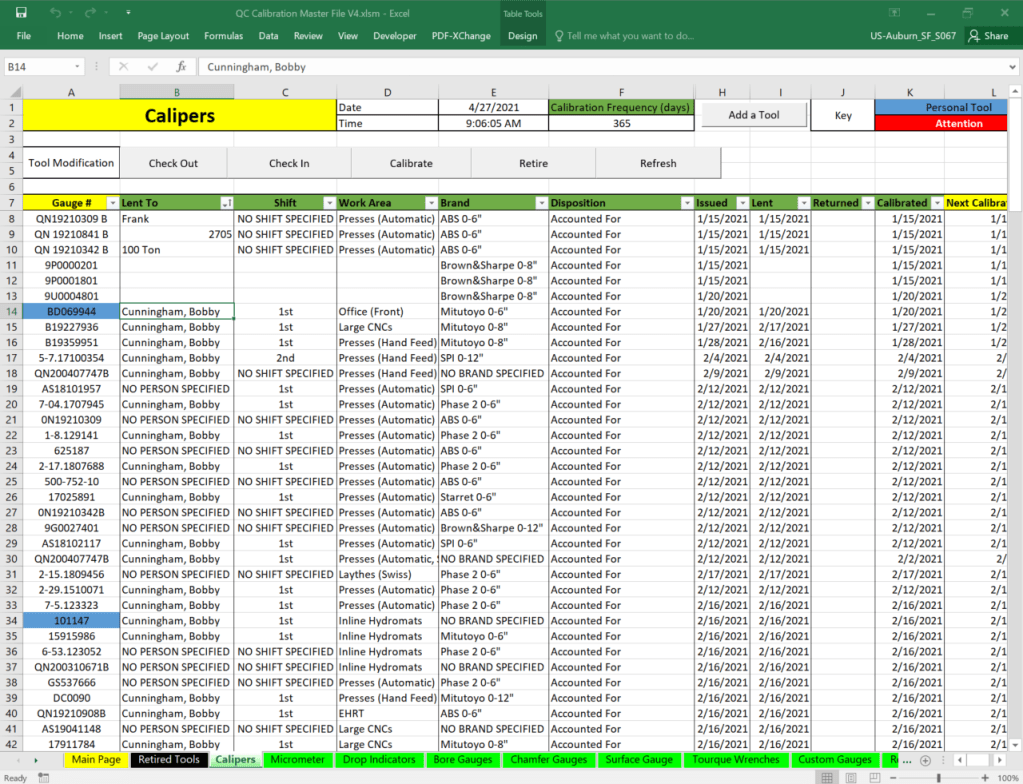

Tool Calibration Tracker

The first and most simple of my sheets at ABB Auburn was the tool calibration tracking sheet. This sheet allowed for the tracking of any number of quality tools’ calibration so that the quality department knew when they expired and where the tools were located. It also keeps track of how and when tools are retired so the department could find patterns in brands or tool owners. The first link is a standard operating procedure on how to calibrate calipers, and it has instructions on how to use the sheet.

For Clubs

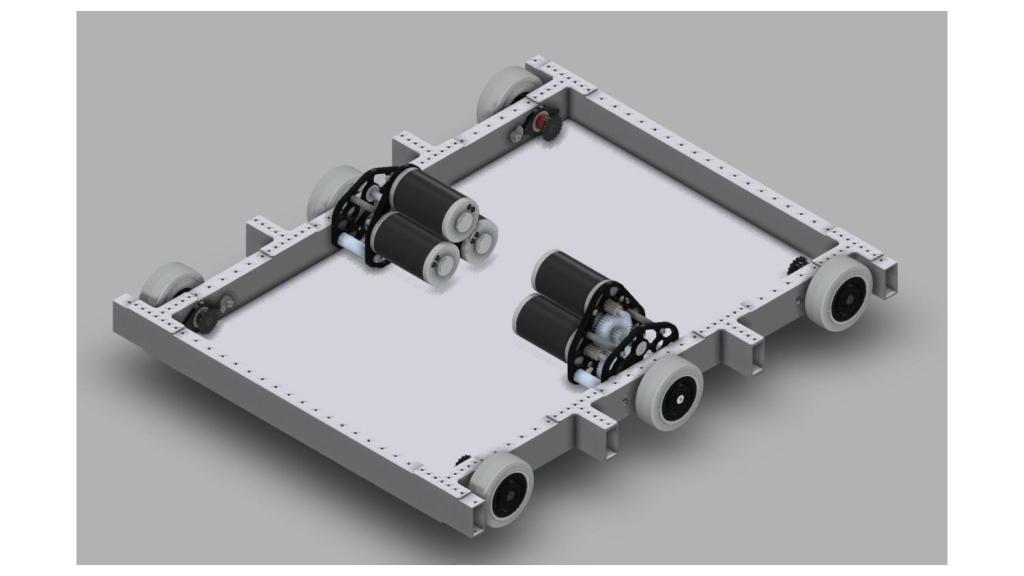

Dynamic Robot Chassis

A Solidworks assembly that uses configurations, equations, and design tables to create a customizable robot chassis. This file helped Wentworth ASME’s Robot in 3 Days team with the rapid design required to meet their deadline.

For Class

Gearbox Project

Easily the project I am most proud of to date. In the course Design of Machine elements, our final project was to create a gearbox based on several technical specifications. Here is the final report with a list of specs, several types of analysis, and pictures of the CAD Assembly. Also attached is a copy of our calculation spreadsheet, the MOAS (mother of all spreadsheets). We received a 96/100 on this project and the 4 points taken off were not related to the functionality of the device.

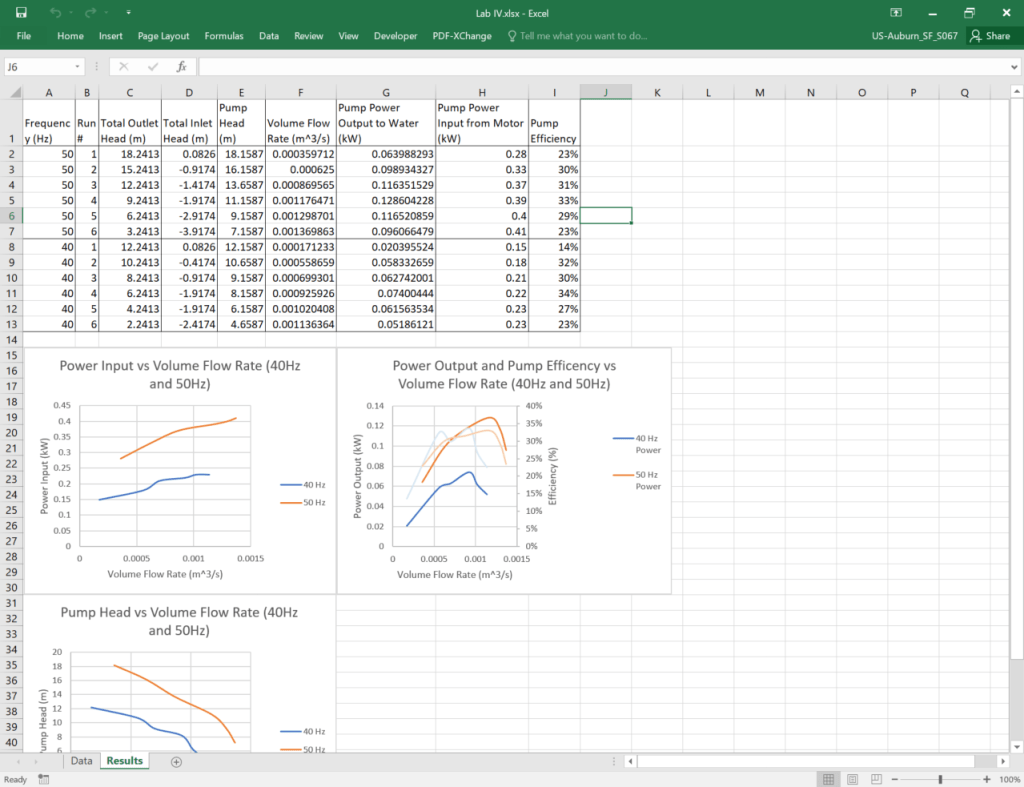

Notable Labs

Here is an example of a typical data analysis sheet I would create for thermodynamics labs. I would often use equations to make the document before I collected the data based on the lab’s write-up. This process saved my group and me hours of hand calculations and yielded fruitful conclusions and data visualization. The two files are the calculation sheet and the final lab report (please note that my contributions to this lab include the spreadsheet, equations section, and data analysis section).

Senior Capstone Project: Compliant Flap

The senior capstone experience at Wentworth is divided into two halves. The first half, which I completed in April of 2022 was dedicated to a full “paper” design of my group’s project. The second half, to be completed in August 2022, entails the actual building and testing portion of the project.

Below is the halfway-point report that goes over the details of the Compliant Flap project, including design processes and technical drawings.

For Fun

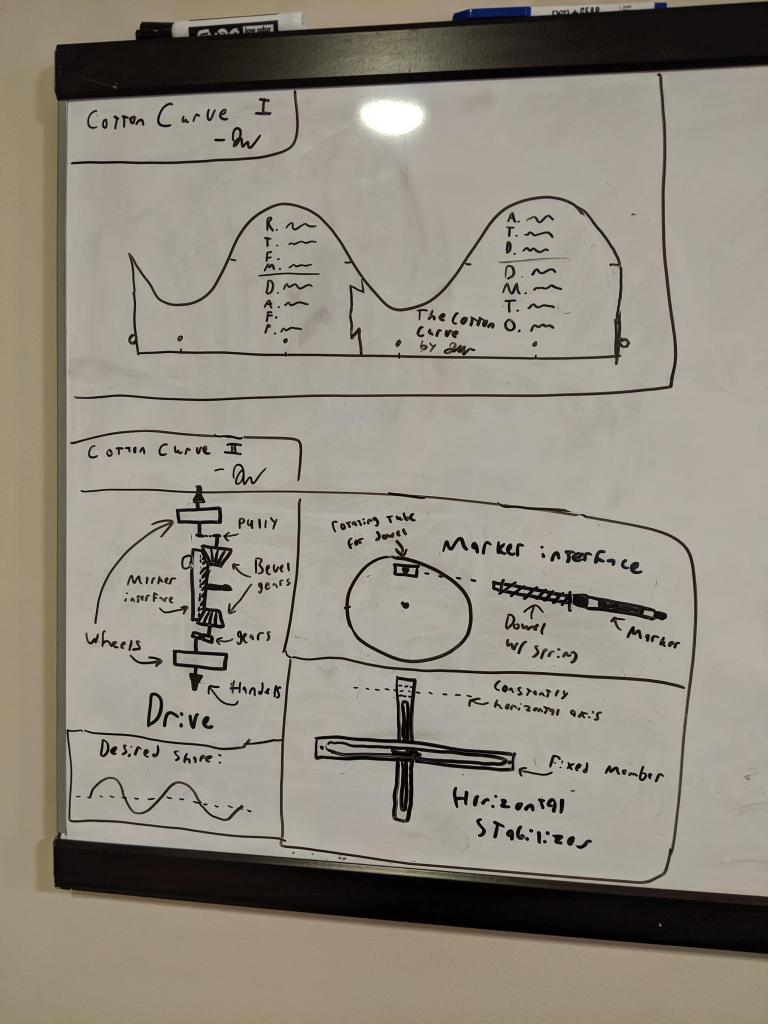

Cotton Curve

Named after my favorite professor, the Cotton Curve is a mechanical sine wave generator. It is designed to have no electronic parts and draw a sine wave of fixed amplitude with any medium on any surface. Here is a useful visualization that demonstrates how this curve is defined in three dimensions. (Forgive the crude drawing above).